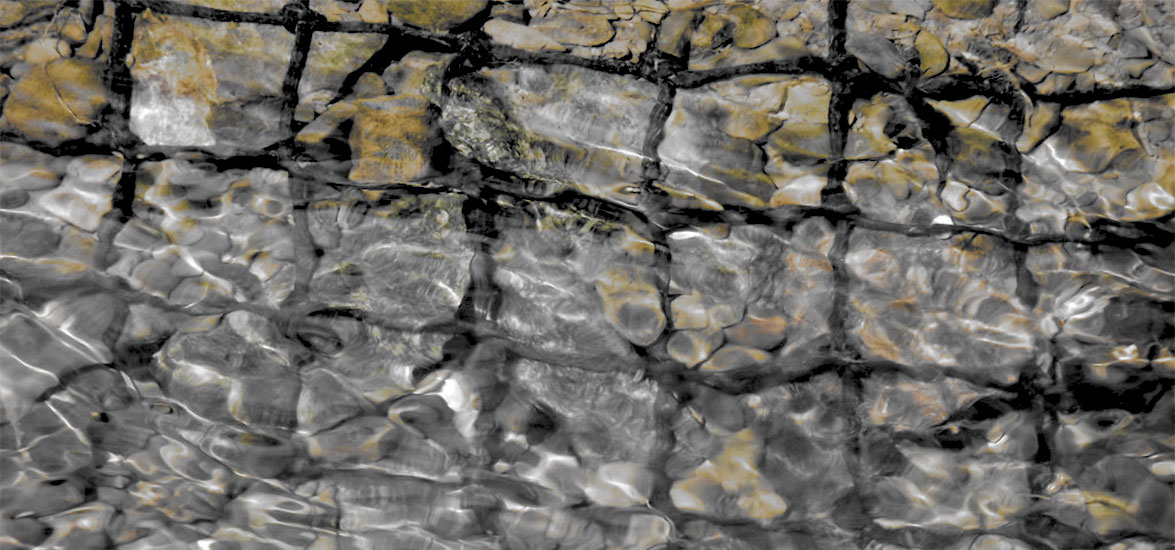

SANDSTONE ROCK ARMOUR REMOVAL 29th April 2015

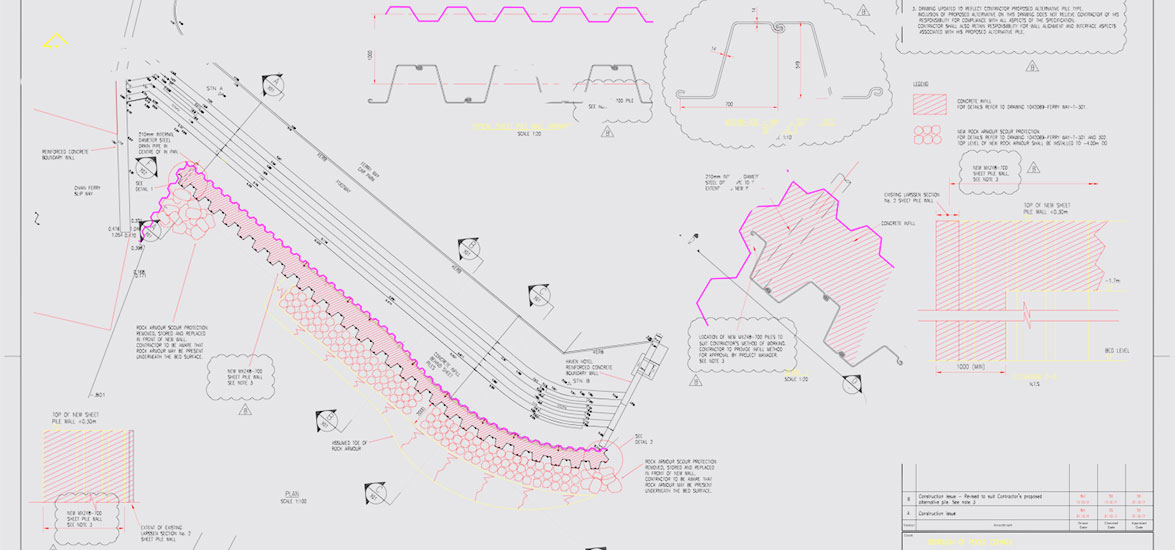

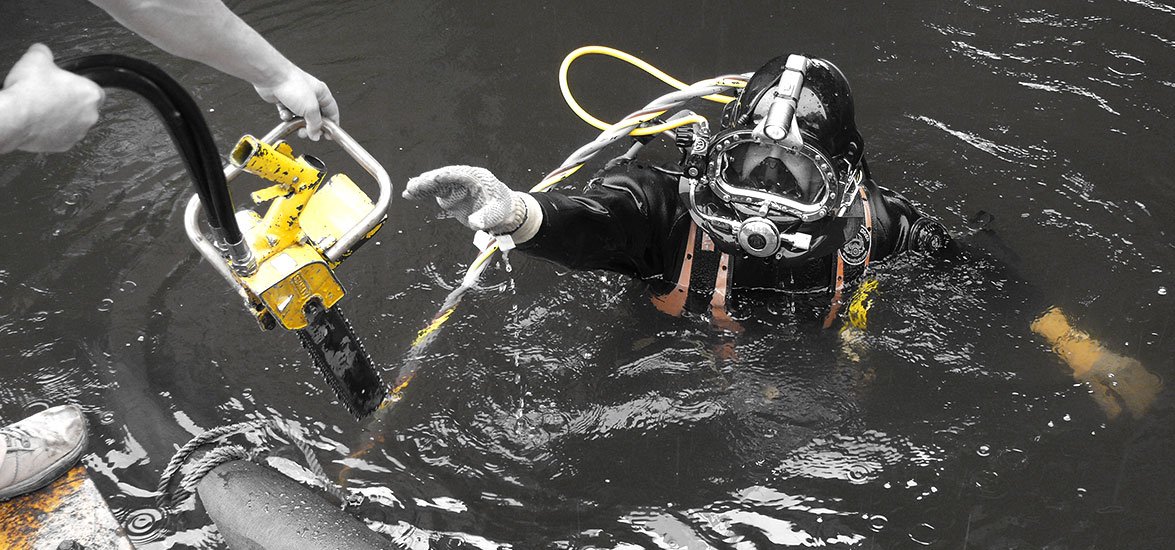

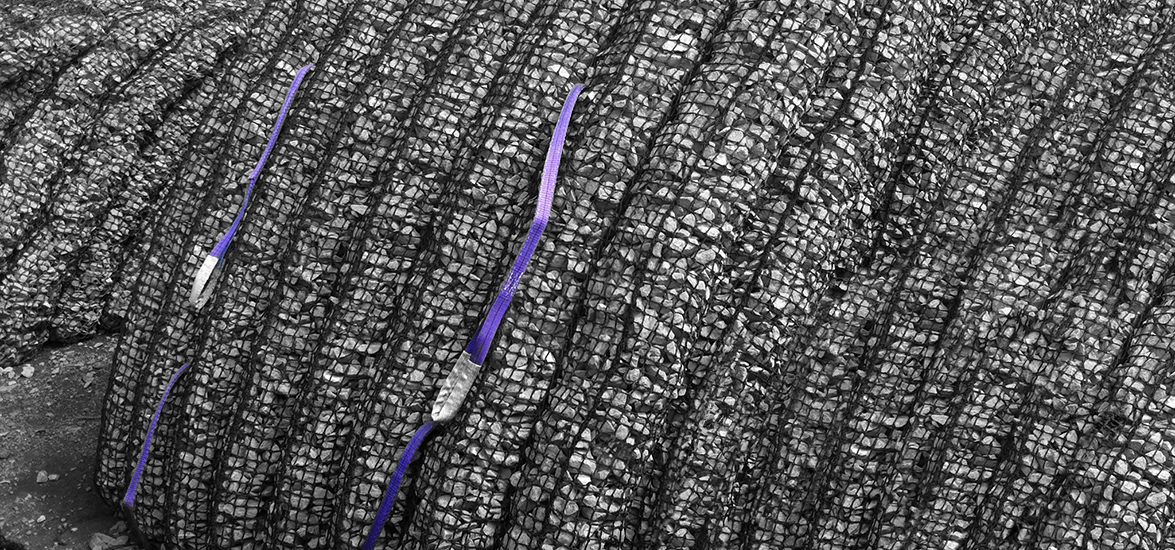

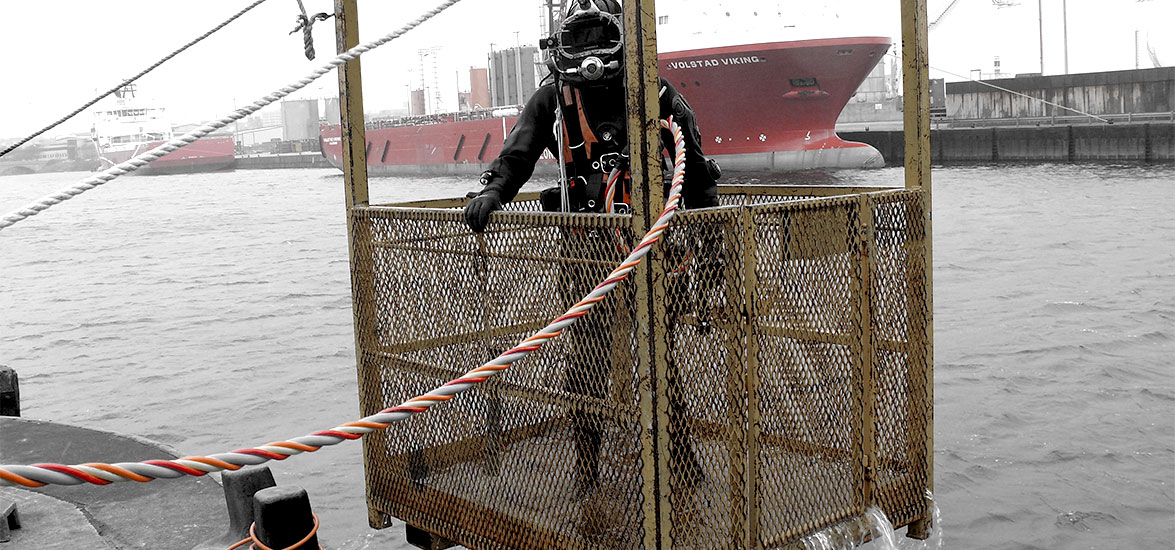

SANDSTONE ROCK ARMOUR REMOVAL PROJECT BRIEF To locate and remove a number of 5 tonne sandstone boulders so that the site contractor could complete the installation of a sheet pile retaining wall. On completion of piling works, rock armour was to be reinstated to provide a suitable means of scour protection. RESPONSIBILITIES I was responsible for interpreting the drawings provided by the client and compiling the dive management system which included everything from the sequence of works to be adopted…