RE-ENGINEER INTERIOR MAST SUPPORT COLUMN

RE-ENGINEER INTERIOR MAST SUPPORT COLUMN

| PROJECT BRIEF |

To rectify distorted interior mast support column on 50′ sailing yacht highlighted during survey. I appointed and co-ordinated 6 skilled specialists to carry out each phase of the works which included riggers, yardmen, shipwrights, fabricators, engineers, and of course the yacht brokers that were marketing the yacht for sale. This was a bespoke project with the initial works to identify why the unit had failed so drastically. It was identified that this issue was predominantly historic from the point of build, however, a re-engineered interior mast column was fabricated in order to support the load from the rig above through to the keel step. |

| RESPONSIBILITIES |

Director of all operations and project manager from inception to completion. To plan the works, to costs the works, to appoint skilled contractors to carry out each phase of the works, to execute the works and manage the works in accordance with work breakdown structure, budget control all of which I ran remotely from Australia. |

| CLIENT |

Private owner |

| CHALLENGES |

Working remotely can present challenges which is why I was very specific in my initial brief prior to departure. Liaisons throughout the lifecycle had to be conducted with consideration for an 8hr time indifference due to my location in Australia. Weather is always a limiting factor when working on vessels not inside the hanger but quality and safety were never compromised. Temperature and moisture control for curing purposes had to be monitored in accordance with manufacturers guidelines in order to not jeopardise the molecular compound of the composites being used. Co-ordinating all personnel can be time consuming but when planned efficiently and effectively the project should be able to move through each phase seamlessly |

| OUTCOME |

All works completed 24% under stakeholders initial budget |

| WORKS EXECUTED |

- Electrics disconnected

- Vessel moved into the crane area, rig unstepped and vessel returned to berth. Rig layed up ashore for the duration of works

- Team brief to discuss works and responsibilities onboard

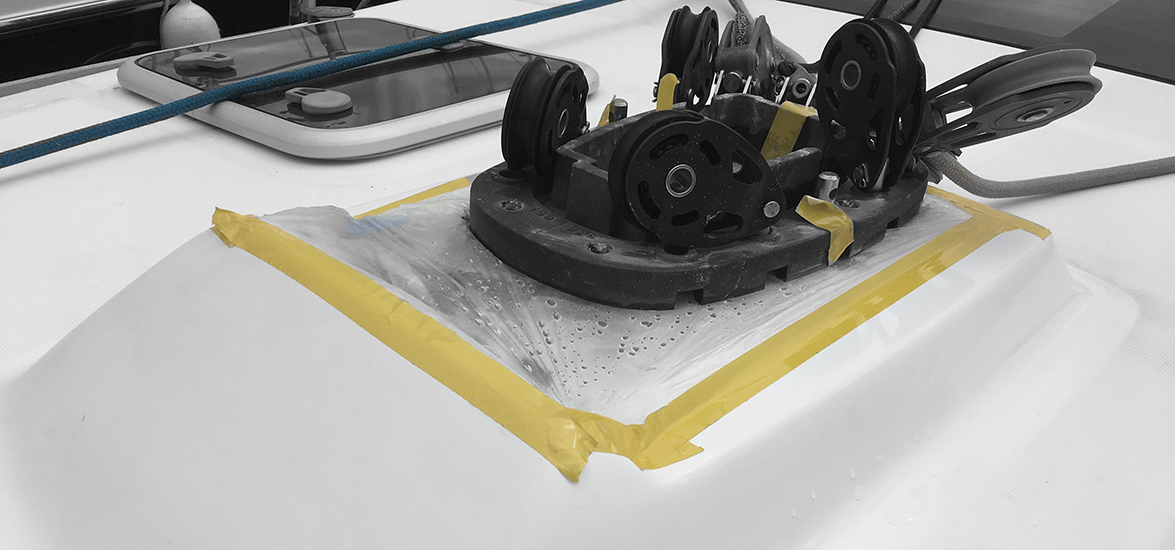

- Exterior deck ring removed to identify if there is any external structural damage/cracking

- Interior mast support column detatched from the deckhead and keel step

- Remove ring of hard filler from deckhead used to fill void between mast step plate and deckhead – this composite had compressed and failed

- Visual check of the deckhead for any signs of structural damage/cracking

- Visual check for any signs of structural damage/cracking of the keel step where the base of the mast suport column was fastened

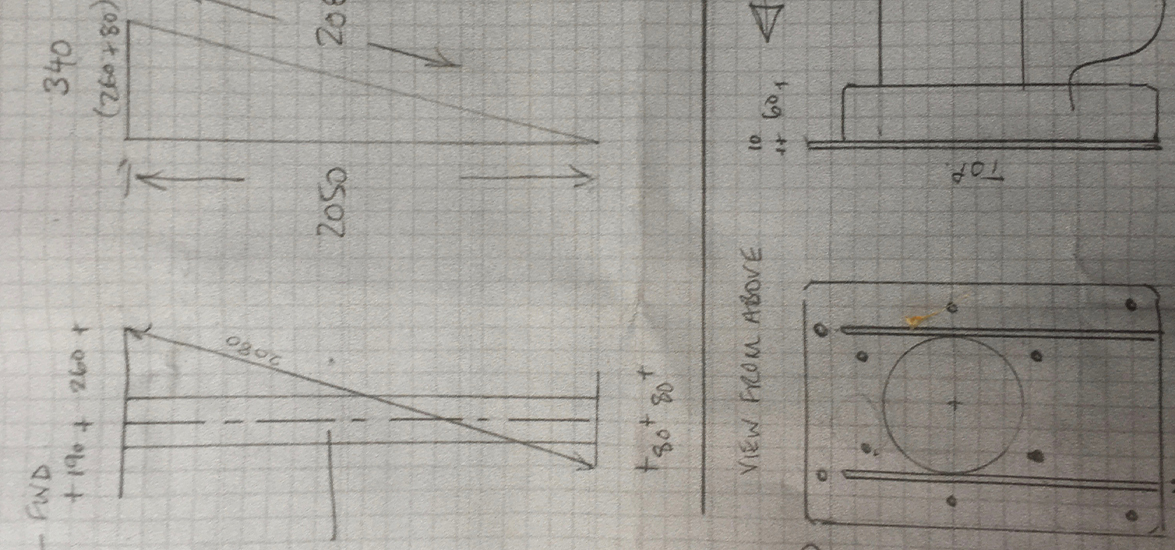

- Mock template of the mast support column fabricated and dry fit to check for positioning and alignment

- Team updated and all agreed the best course of action is to not use composite filler but instead increase the thickness and surface area of the mast column deckhead plate and keel step plate. Modifying the plate thicknesses will provide greater strength and load carrying capabilities

- Additional fabrication of webs running longitudinally fore and aft either side of the interior mast column will provide additional stiffness and support to the plate which will be through bolted to the exterior deck ring

- Exterior hairline cracking on in gel coat prepared, mixed, applied, cleaned, finished

- The shipwright used a slow cure resin mix with milled fibres and microfibres on both the deckhead and base plate to ensure a good bond was formed and to ensure a good fit filling any deviations or shallow voids

- Once the deckhead was bolted up and all surpluses cleared away, the deck ring was fitted

- The base plate was seated on the same resin mix as the deckhead with the additional requirement for packers being fitted. These were bolted into place with a final shim knocked into position with a hammer to ensure a tight fit from deckhead to keel step

- Due to fixing the deckhead up flush with the grp and packers being used on the base plate it meant that the base plate was now positioned at soleboard height. In order to keep this tidy and aesthetically pleasing to the eye, the soleboards surrounding the mast support column were cut to fit around the base. This allows full functionality of being able to lift and lower the soleboards without hinderance

- On completion of all interior works, exterior gel coat works and deck ring fitting, the vessel was moved into the crane area and the rig stepped

- The Engineer was on site during the rig stepping process

- All electrics mounted within the headlining were re-connected and tested

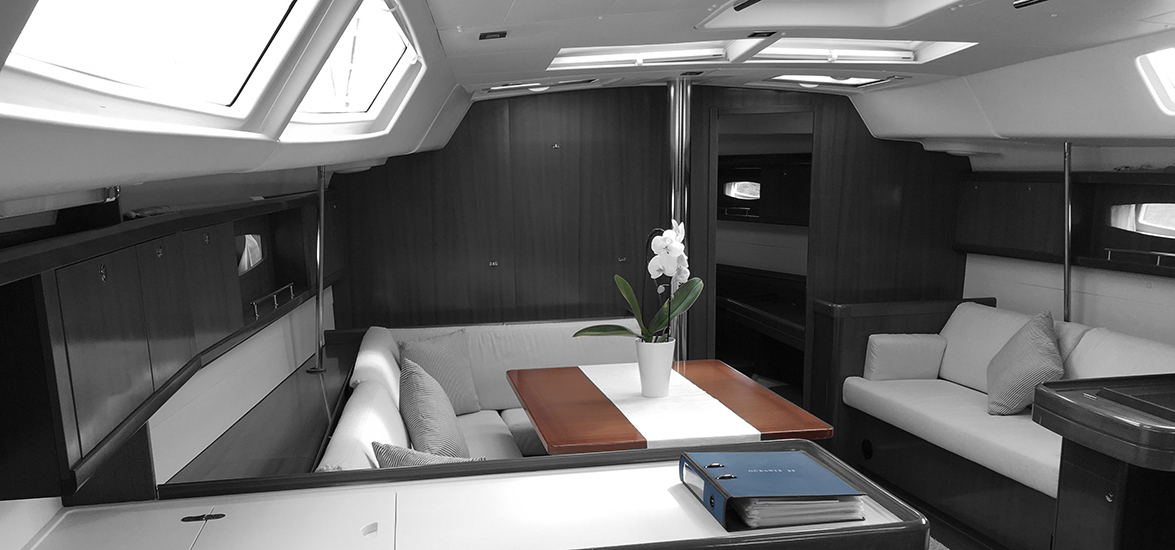

- All protective coverings were finally removed and the interior upholstery re-fitted

|