HEAVY DUTY CONTAINMENT DESIGN

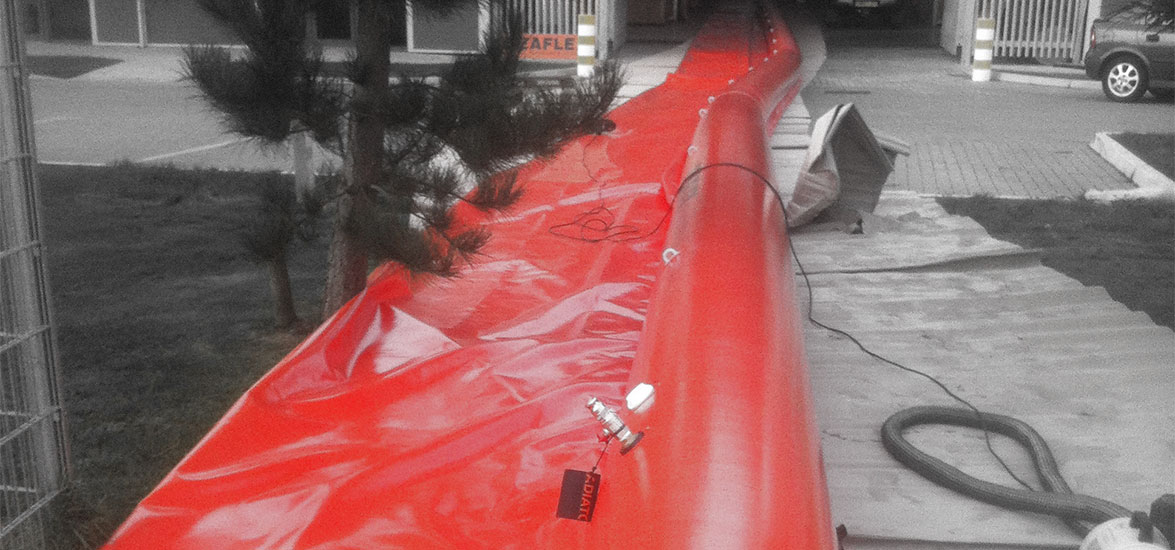

HEAVY DUTY CONTAINMENT CURTAIN DESIGN

| PROJECT BRIEF | To re-design and collaborate with a reputable fabricator a heavy-duty permeable containment curtain measuring 60m x 4m capable of withstanding the demands of fast flowing waterways. The curtain would be used to protect the main watercourse from contamination during the subsurface engineering works carried out by my commercial diving company. |

| RESPONSIBILITIES | Project Manager | Collaborative designer responsible for conveying the specification of the product required and its key design features to the fabricator having experience in working with containment curtains and the demanding conditions of fast flowing waterways. This project had to be designed, fabricated and deployed onsite within 3 weeks in an effort to meet a very stringent and non-negotiable deadline. I was responsible for ensuring that this ran to schedule. |

| CLIENT | MMC Diving Services for Aquatic Engineering | Dyer & Butler | Network Rail |

| CHALLENGES | This curtain had to withstand substantial flows in excess of 30 cumecs, a large area of rock armour and floating debris. It had to be indestructible, offer protection to the local environment from contamination but pliable to be deployed and retracted in adverse conditions. Hazards included abutments, cutwaters and pier structures that supported a mainline rail link owned by Network Rail within close proximity. Securing the curtain both to the riverbank and riverbed required lateral thinking with the inclusion of quick release mechanisms to quickly and safely remove the unit in the event of an emergency. |

| RISK RATING | Medium Risk |

| OUTCOME | The unit was successfully manufactured by Seaflex Ltd and delivered on site within the elected time frame. A second unit was fabricated as a spare and both are used for on-going works in fast flowing rivers. |

Project Details

Skills : Construction Works, Design and Fabrication, HSEQ, Project Management