A.L.B INVERSION LINE TESTING

A.L.B INVERSION LINE TESTING

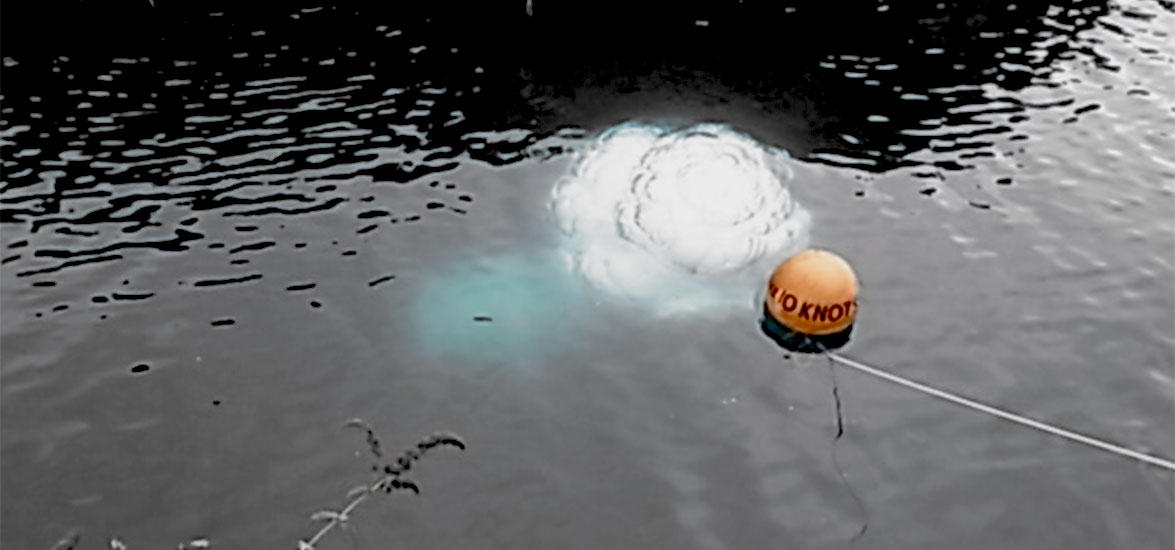

| PROJECT BRIEF | The brief was to rig and capture the inversion process of both a 5 tonne and 10 tonne A.L.B (Air lift bag). Both units were secured to a 19 tonne DMA (Dead Mans Anchor) at depth. Once fully inflated the bags were released from the DMA via a 10t SWL release hook. The client was a global company specialising in underwater air lift bags and buoyancy systems for both inshore and offshore projects with this project forming part of their quality assurance and testing process. |

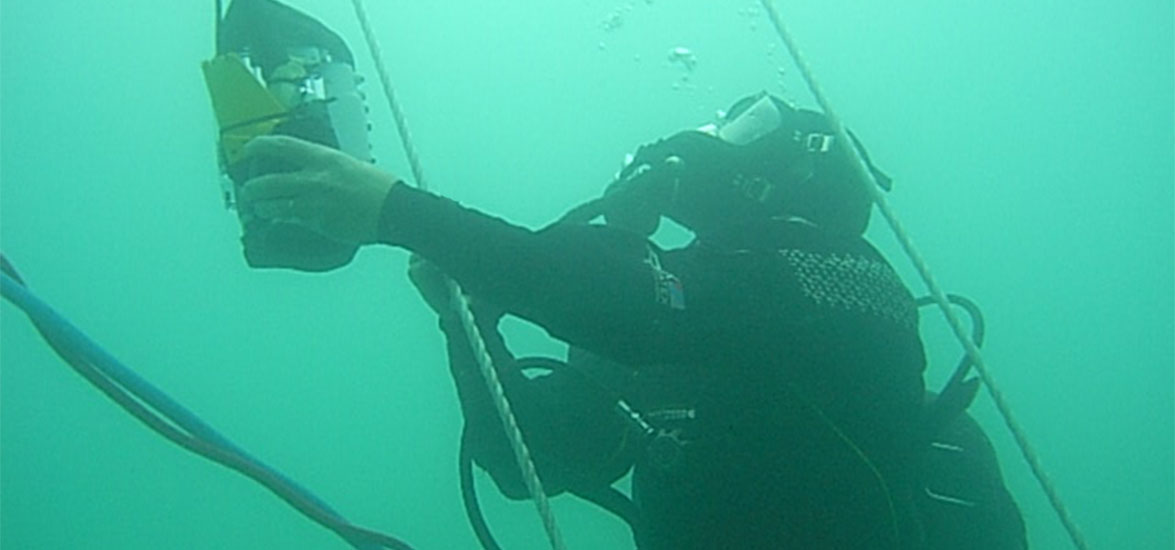

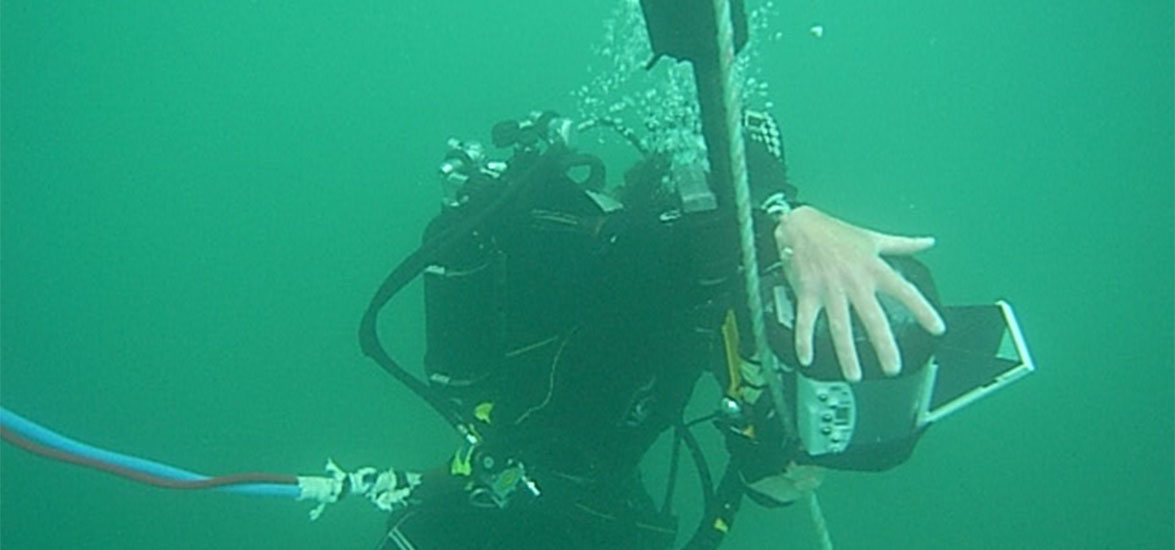

| RESPONSIBILITIES | I was the director of operations and projects manager responsible for the risk assessment strategies, dive permits, equipment logistics and personnel welfare. I was also the diver responsible for setting up the underwater camera systems to capture the shot as the trigger was activated. This image can be viewed at https://www.youtube.com/watch?v=n4lGHg_kDNM#t=74 |

| CLIENT | MMC Diving Services | Seaflex Ltd |

| CHALLENGES | The nature of this project was extremely dangerous and challenging. Subsea lifting operations always carry an inherently high risk and potentially volatile environment. Rigging up a camera system mid water close enough to capture the trigger mechanism and inversion but far enough away not to be blown out of the water was critical to the overall project. This project was carried out at depth with all equipment being sent to the DMA via a tabernacle pulley system to reduce bounce dives and fatigue on the divers. The ALB was rigged to a strain gauge load cell and compressor with divers and all personnel vacating the area during the filling process. |

| RISK RATING | High Risk |

| OUTCOME | Project completed |

Project Details

Skills : Commercial Diving, Director of Operations, HSEQ, Lifting Operations, Logistical Planning, Project Management